Products

Optimize your research!

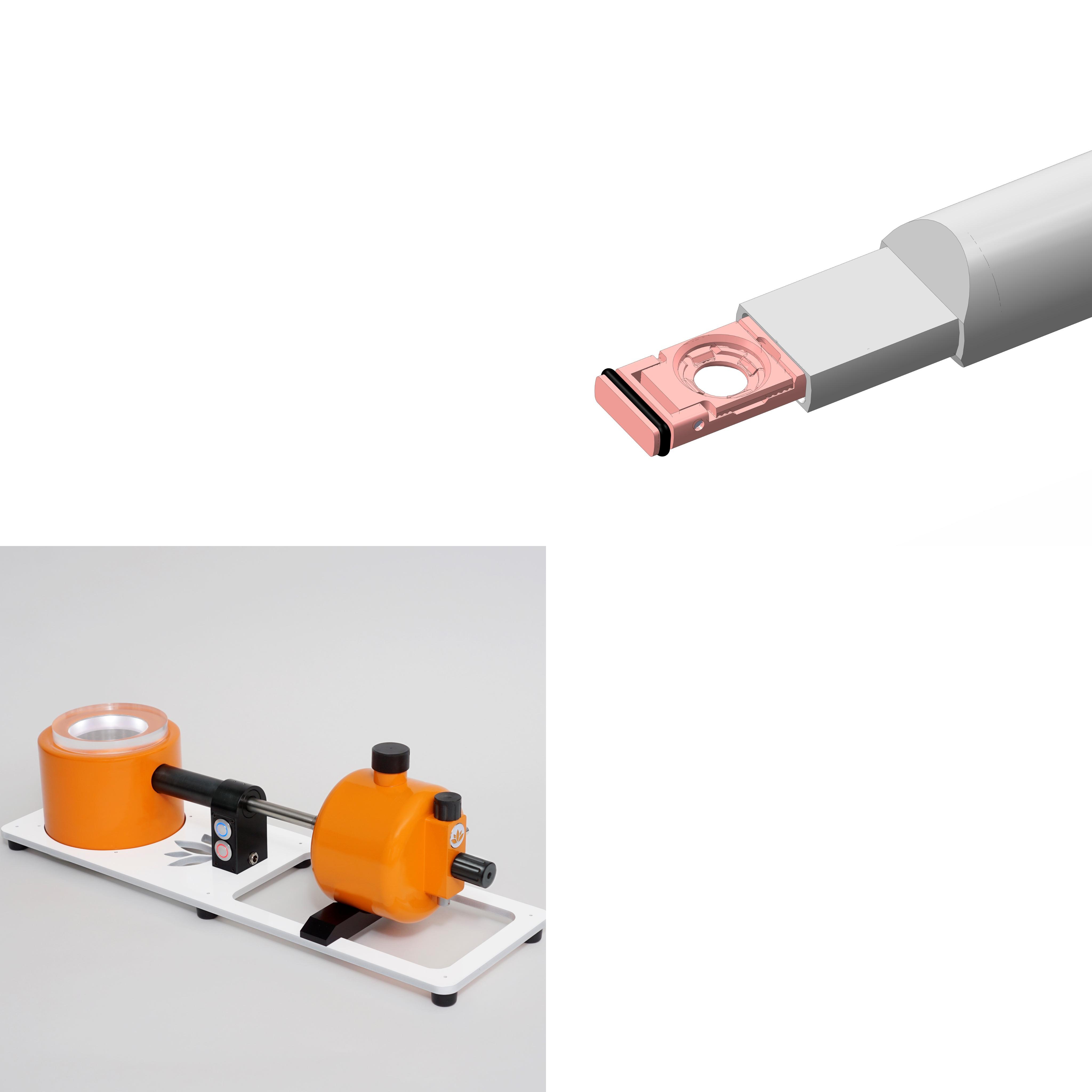

Cryogenic TEM specimen holders

Answer: The holder has a tip thickness of 1.5mm. It is designed for an alpha tilt of +/- 70 degrees. Please note that the maximum tilt is mainly determined by the pole pieces of your TEM. Please consult with your TEM manufacturer (providing the 1.5mm value for our tip height) and/or Simple Origin for specific information.

Answer: Please use an oil-free pumping system that includes a turbo pump. A desired dewar vacuum is in the low 10-6 torr range. It is usually recommended to pump the dewar overnight before using it. The activated charcoal regeneration is required less often and should be typically performed once per week to once per month (in case the dewar is vented accidentally, longer pumping and multiple activated charcoal regeneration is required). A clear indication of required pumping and/or activated charcoal regeneration is noticeable condensation on the outer dewar surface.

Answer: Our Dual Grid/Autogrid Cryo Transfer Holders are designed to achieve steady state drift values below 3 nm/min with a resolution better than 2 Å during regular operations.

It is important to note that drift and resolutions are dependent on various parameters such as TEM performance, objective lens, sample, and camera conditions.

The overall baseline reference for the achievable values is usually set by the performance of the TEMs standard single tilt holder at room temperature.

Answer: The Dual Grid/Autogrid Cryo Transfer Holder has a steady state holding time of ~10 hrs. Our cryo holders work seamlessly with the Cryogen Refilling System that allows for extended automatic data acquisition time of up to ~48 hrs.

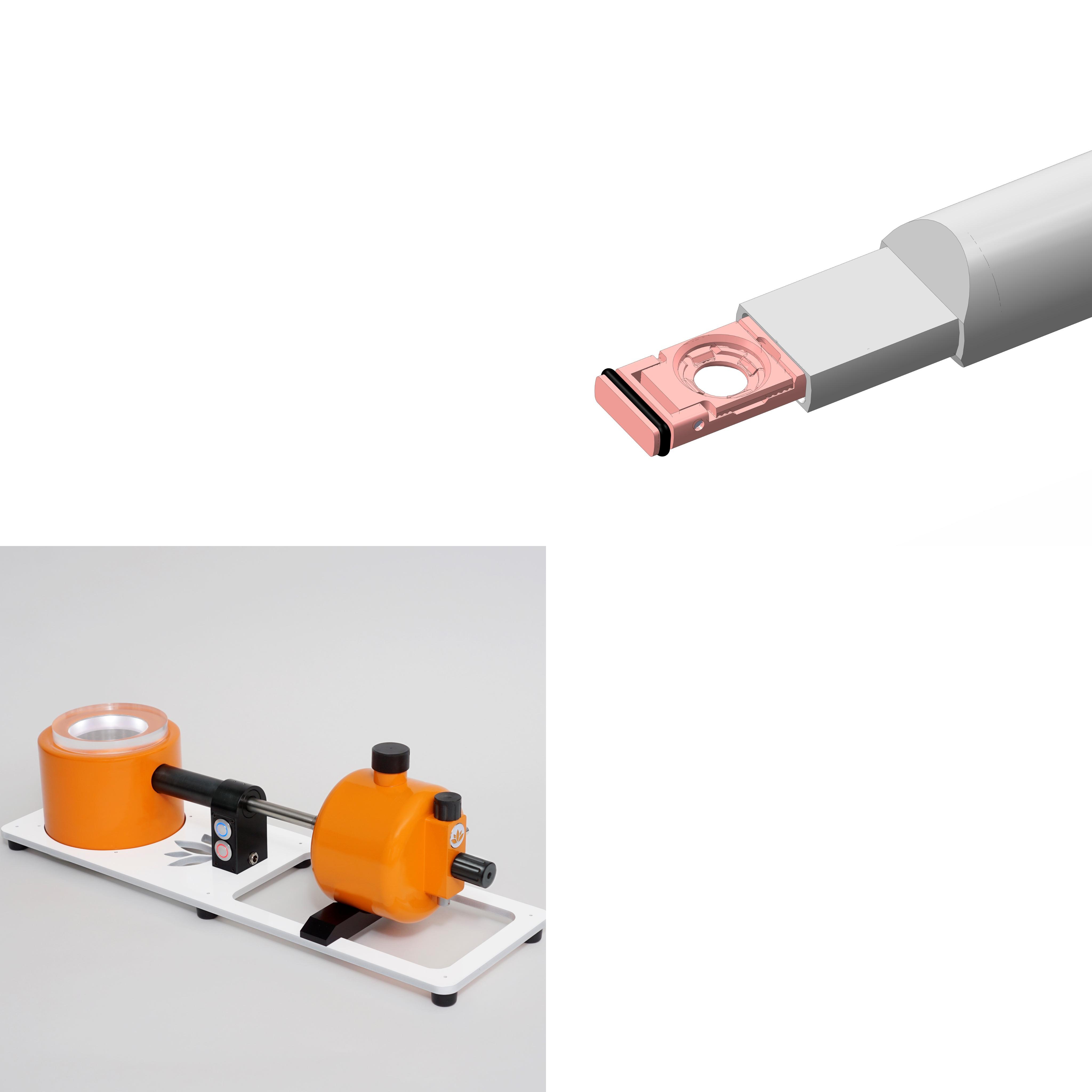

Answer: The workstation is typically filled with liquid Nitrogen up to the holder Tip. The Tip is surrounded by cold nitrogen gas during sample loading.

Answer: In the Dual Grid/Autogrid Cryo Transfer Holder we use a calibrated silicon diode that is located ~25 mm away from the sample position.

Answer: We usually achieve transfer temperature < -175°C. This is well sufficient to prevent recrystallization of amorphous ice.

Answer: Typical steady state tip temperatures are below -175°C.

Answer: It takes 15-30 minutes to achieve temperatures below -175°C independent of tip extraction. Allowing enough time for that cool down process is recommended to maintain good sample quality.

Answer: It is recommended to store the holder under vacuum on the pumping station.

Answer: To warm up the workstation and the Dual Grid/Autogrid Cryo Transfer Holder it is recommended to:

Answer: Using appropriate plasma cleaners enables the removal of hydrocarbons from the holder tip.

Answer: Place the CRYOGENIC INERT GAS/VACUUM TRANSFER HOLDER in a glove box that is either evacuated or filled with an inert gas such as Argon. Load the sample in the glove box. Once the sample is loaded into the holder, retract the holder tip into the barrel. This seals the sample in the inert gas or vacuum environment with the help of the O-ring on the tip. Transfer the holder to the TEM and place it in the TEMs pre-pump position. Extract the holder tip and wait till the argon gas is pumped out. Insert the holder completely into the TEM Column and then cool it.

Answer: Having the O-ring on the tip makes it easier to inspect it and replace it if required.

Answer: Usually an inert gas is preferred in terms of maintaining a non-oxidizing atmosphere around the sample for an elongated time period. Due to the pressure differential, the use of vacuum reduces the duration for which the sample is protected.

Answer: After loading the sample in an inert gas atmosphere within the glove box, you can cool the holder in the TEMs pre-pump position with the sample tip sealed in the retracted position in the presence of the inert gas. You can extract the tip once the sample is cold and then insert the holder into the TEM column.

Answer: Please contact us to discuss your application- support@simpleorigin.us

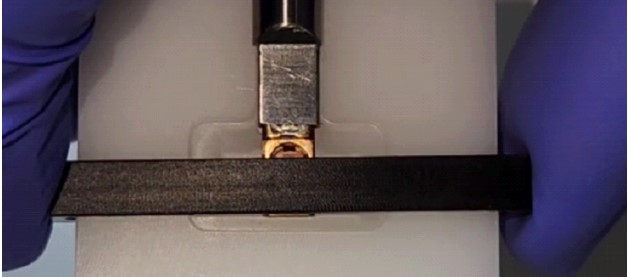

Answer: The holder is designed to make this process user friendly. For convenience, the sample clamp can be opened outside the glove box. Closing the clamp is assisted by a moveable bar. After inserting the grid in the holder, simply flip the clamp over using a tweezer and then move the bar over the clamp and press down with your finger or a tool.

Answer: The pump down time may vary based on the type of inert gas used. It is recommended to discuss the specific gas with the TEM manufacturer so that they can install the appropriate pump.

Answer: Heating from -160°C to -150°C takes just a few seconds. Allow a few minutes for stable temperature regulation (to minimize specimen drift).

Answer:Yes. The design of the clamp and the required tools are identical.

Answer:

Answer: The refilling system dewar is 10 liters. You can get up to 48 hrs of unattended data collection using the system.

Answer: We have a patented sensor for the cryo specimen holder dewar as well as the ACD (cryo trap) dewar. This sensor detects the liquid nitrogen level during refills and closes the valves to prevent liquid nitrogen from overflowing during refills.

Answer: Yes, we make the sensor for all the commercially available cryo sample holders.

Answer: Yes, the refilling system can fill both the holder and the ACD dewar. This selection can be made in the user interface. The GUI has an option for the user to select each dewar independently for refills.

Answer: Presently, the system is integrated with TVIPS data collection software EM-Menu. We are working on integrating it with Serial-EM in the near future.

Answer: The system communicates with the camera/TEM PC and continuously writes the system parameters to the windows registry. These can be used to monitor and start/stop the system remotely.

Answer: Users usually refill the Gatan 626 holder every 3 hrs and it takes about a minute to fill it.

Answer: The system is designed by keeping in mind the complete data collection process. Some of the safety features include:

At Simple Origin, our team is motivated to solve engineering challenges using innovative solutions. Our mission is to collaborate with scientists to identify and develop next generation research instruments.

p.deshmukh@simpleorigin.us

Join our team and make a difference.

We are hiring for these positions.

This is an exciting opportunity to join a dynamic team at the forefront of materials characterization and electron microscopy. You will play a critical role in enabling customers to unlock the full potential of our technology.

To apply, please send your resume and a brief cover letter to Support@simpleorigin.us.